Fabrication Division

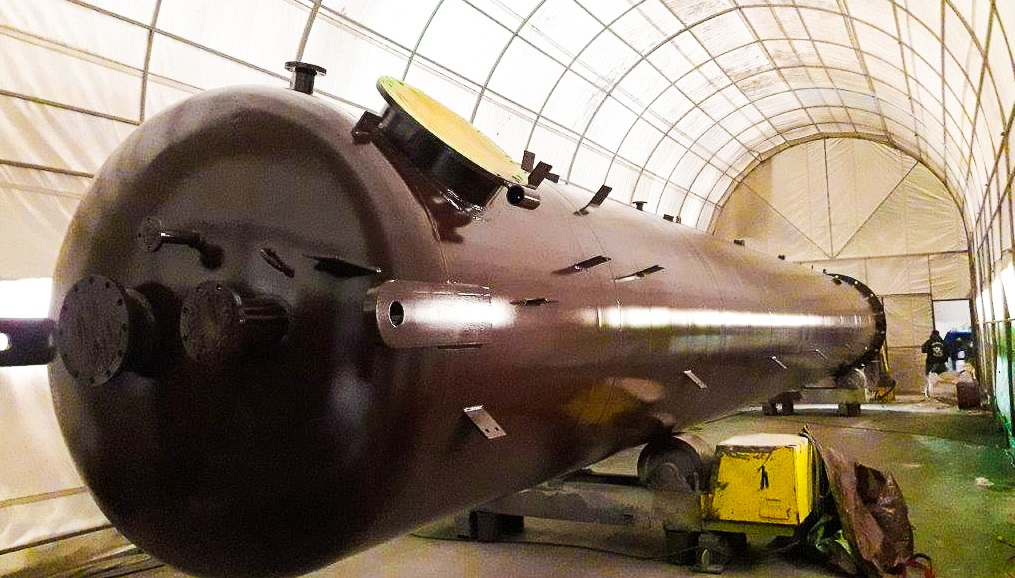

Superior Boiler Works and Welding Limited has been Manufacturing Boilers, Heat Exchangers, Pressure Vessels, Tanks and Piping for over 59 Years. Superior has a state-of-the-art manufacturing facility on 13.5 acres in Stoney Creek, Ontario, Canada. The facility is equipped with a 180-ton lifting capacity with 42 feet under the hook. Superior excels in complex projects that require special capabilities involving:

- Special Engineering, Design, Fabrication and Construction considerations

- Vessels for cyclic service

- High pressure and high temperature designs

- Projects requiring exotic materials

- High alloy material: chrome molybdenum alloy steels, corrosion persistent alloys, heat resistant alloys, high temperature alloys, H.I.C resistant materials, duplex steels, carpenter 20cb-3, alloy 20, titanium steel

- Clad vessels

- Vessels with dimple, half pipe jackets and with heating coils

...

...

| Certificate Number | ASME | Designation |

|---|---|---|

| 2551 | Manufacture and assembly of power boilers at Superior Boiler Works and Welding Limited and field sites controlled by Superior Boiler Works and Welding Limited | S |

| 25511 | Manufacture of pressure vessels at Superior Boiler Works and Welding Limited and field sites controlled by Superior Boiler Works and Welding Limited (This authorization does not cover impregnated graphite) | U |

| 42797 | Heating boilers except cast iron and cast aluminum at Superior Boiler Works and Welding Limited and field sites controlled by Superior Boiler Works and Welding Limited | H | 49765 | Manufacture of Class 1 and Class 2 pressure Vessels at Superior Boiler Works and Welding Limited and field sites controlled by Superior Boiler Works and Welding Limited | US |

| NATIONAL BOARD | ||

| NB | Superior Boiler Works and Welding Limited is authorized to apply the “NB” mark and register boilers, pressure vessels and or other pressure retaining items in the National Board | ASME Designator(s): H, S, U, U2 |

| 9644R | Superior Boiler Works and Welding is authorized to use the “R” symbol. All activities within the scope of this Authorization shall be controlled by Superior Boiler Works and Welding Limited. The Scope of this Authorization is limited to Metallic Repairs and Alterations at Shop and Field Locations | The provisions of the National Board Inspection Code and NB‐ 415, Accreditation of “R” Repair Organizations |

| TSSA | ||

| QA 161 | Manufacture of pressure vessels at Superior Boiler Works and Welding Limited and field sites controlled by Superior Boiler Works and Welding Limited | ASME Boiler and Pressure Vessel Code, Section VIII, Division 1 and CSA Standard B51, Boiler, Pressure Vessel and Pressure Piping Code |

| QA 00671 | Fabrication, assembly, and repair of power piping at Superior Boiler Works and Welding Limited and fabrication, assembly, erection, and repair of power piping at field site controlled by Superior Boiler Works and Welding Limited | CSA Standard B51, Boiler, Pressure Vessel and Pressure Piping Code and ASME B31.1 Power Piping |

| QA 00672 | Fabrication, assembly, and repair of process piping at Superior Boiler Works and Welding Limited and fabrication, assembly, erection and repair of process piping at field sites controlled by Superior Boiler Works and Welding Limited | CSA Standard B51, Boiler, Pressure Vessel and Pressure Piping Code and ASME B31.3 Process Piping |

| QA 00893 | Repair and alteration of boilers, pressure vessels, piping and A, B, C, D, E, F, and H type fittings at Superior Boiler Works and Welding Limited and for repairs and alterations at field sites controlled by Superior Boiler Works and Welding Limited | CSA Standard B51, Boiler, Pressure Vessel and Pressure Piping Code |

| QA 02248 | Manufacture and assembly of power boilers at Superior Boiler Works and Welding Limited and field sites by Superior Boiler Works and Welding Limited | ASME Boiler and Pressure Vessel Code, Section I, and CSA Standard B51, Boiler Pressure Vessel and Pressure Piping Code |

| QA 02249 | Fabrication of Welded and Non‐Welded Category A, B, D, E, F, and H type Fittings only at Superior Boiler Works and Welding Limited | CSA Standard B51 Boiler, Pressure Vessel and Pressure Piping Code |

| QA 02734 | Fabrication, assembly, and repair of refrigeration piping at Superior Boiler Works and Welding Limited and fabrication, assembly, erection, and repair of refrigeration piping at field sites controlled by Superior Boiler Works and Welding Limited | CSA Standard B52, Mechanical Refrigeration Code and ASME B31.5 Refrigeration Piping |

| QA 03593 | Heating boiler except cast iron at Superior Boiler Works and Welding Limited and field sites controlled by Superior Boiler Works and Welding Limited | ASME Boiler and Pressure Vessel Code, Section IV and CSA Standard B51, Boiler Pressure Vessel and Pressure Piping Code |

| QA 05098 | Manufacture of pressure vessels at Superior Boiler Works and Welding Limited and field sites controlled by Superior Boiler Works and Welding Limited | ASME Boiler and Pressure Vessel Code, Section VIII, Division 2 and CSA Standard B51, Boiler, Pressure Vessel and Pressure Piping Code |

| QA 06183 | Fabrication, assembly, and repair of nonflammable medical gas piping at Superior Boiler Works and Welding Limited and fabrication, assembly, erection and repair of nonflammable medical gas piping at field site controlled by Superior Boiler Works and Welding Limited | CSA Standard B51, Boiler, Pressure Vessel and Pressure Piping Code and CSA‐Z7396.1 Nonflammable Medical Gas Piping Systems |